In the world of woodworking, home improvement, and DIY projects, sandpaper grit is a term that holds significant importance. It’s the key to achieving that perfectly smooth and polished finish on wood, metal, or any other surface you’re working on. But what exactly is sandpaper grit, and why does it matter so much in various applications? In this article, we will delve into the fascinating world of sandpaper grit, exploring its types, uses, and the science behind it.

Understanding Sandpaper Grit

Before we delve into the depths of sandpaper grit, let’s start with the basics. Sandpaper is a versatile abrasive material used for smoothing and shaping surfaces. It consists of abrasive particles adhered to a paper or cloth backing. The abrasive particles, which are typically made of aluminum oxide, silicon carbide, or garnet, are the stars of the show when it comes to sandpaper’s effectiveness.

Grit, in the context of sandpaper, refers to the size of these abrasive particles. It is usually measured in units known as grit numbers. The grit number indicates the coarseness or fineness of the abrasive particles on the sandpaper. Lower grit numbers represent coarser particles, while higher grit numbers signify finer particles.

Common Grit Sizes

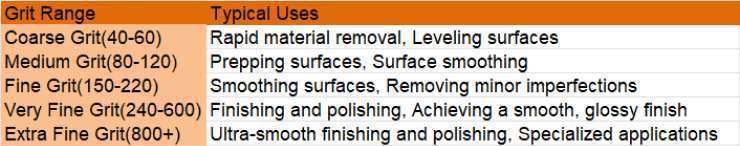

Sandpaper grit sizes can vary widely, but there are some common ranges that you’ll encounter:

- Coarse Grit (40-60): Coarse-grit sandpaper is ideal for tasks that require rapid material removal or leveling surfaces, such as removing paint, rust, or heavy surface imperfections.

- Medium Grit (80-120): Medium-grit sandpaper strikes a balance between material removal and surface finish. It is often used for prepping surfaces before applying paint or finishes.

- Fine Grit (150-220): Fine-grit sandpaper is suitable for smoothing surfaces and removing minor imperfections. It’s commonly used in between coats of paint or finish to achieve a smooth finish.

- Very Fine Grit (240-600): Very fine-grit sandpaper is used for finishing and polishing surfaces. It’s ideal for achieving a smooth, glossy surface.

- Extra Fine Grit (800+): Extra fine-grit sandpaper is used for ultra-smooth finishing and polishing. It’s often employed in specialized applications like fine woodworking or automotive detailing.

Choosing the Right Grit

Selecting the right grit for your project is crucial, as it can significantly impact the outcome. Using the wrong grit can lead to inefficient work or surface damage. Here are some guidelines to help you choose the appropriate grit for your task:

- Material Type: Consider the material you’re working on. Coarser grits are suitable for tougher materials like metal or hardwood, while finer grits are better for delicate surfaces like furniture or car paint.

- Task Objective: Determine your task’s primary objective. Are you removing material, smoothing, or polishing? Coarse grits are for material removal, while finer grits are for finishing.

- Surface Condition: Assess the current condition of the surface. Heavily damaged or uneven surfaces may require starting with a coarser grit before progressing to finer ones.

- Progression: For optimal results, use a progression of grits. Start with a coarser grit to remove imperfections and gradually move to finer grits for a smoother finish.

The Science Behind Sandpaper Grit

Understanding the science behind sandpaper grit can help you make more informed decisions when selecting and using sandpaper for your projects. It’s all about the abrasive particles and how they interact with the material you’re working on.

- Cutting Action: When you rub sandpaper against a surface, the abrasive particles cut into the material. Coarser grits have larger, more aggressive particles that remove material quickly, while finer grits have smaller particles for finer cuts.

- Surface Scratching: As the abrasive particles cut into the material, they create scratches on the surface. These scratches are more visible with coarser grits and become less noticeable as you progress to finer grits.

- Material Removal: Coarser grits remove material more rapidly but leave a rougher surface. Finer grits remove material more slowly but yield a smoother finish.

- Abrasive Hardness: The hardness of the abrasive particles also plays a role. Silicon carbide, for example, is harder and more aggressive than aluminum oxide, making it suitable for tasks where rapid material removal is needed.

- Abrasive Fracture: During use, abrasive particles can fracture, exposing fresh cutting edges. This self-sharpening action prolongs the life of the sandpaper.

Applications of Sandpaper Grit

Sandpaper grit finds applications in various industries and DIY projects. Here are some common uses:

- Woodworking: Sandpaper is essential in woodworking for shaping, smoothing, and finishing wooden surfaces. It’s used in tasks ranging from rough sanding to fine detailing.

- Metalworking: In metalworking, sandpaper grit is used for deburring, polishing, and removing rust or old paint from metal surfaces.

- Automotive: Automotive enthusiasts rely on sandpaper for tasks like bodywork preparation, paint removal, and finishing to achieve a flawless, glossy finish.

- Home Improvement: Whether you’re refinishing furniture, preparing walls for painting, or restoring a deck, sandpaper plays a crucial role in home improvement projects.

- Arts and Crafts: Artists and crafters use sandpaper for various creative applications, including shaping sculptures, distressing surfaces, and achieving unique textures.

Conclusion

Sandpaper grit may seem like a simple concept, but it’s the foundation of achieving smooth and polished surfaces in countless applications. By understanding the different grit sizes and their uses, as well as the science behind abrasive particles, you can make informed decisions to enhance the quality of your projects. So, the next time you reach for that sheet of sandpaper, remember that it’s not just paper with some grit – it’s a tool that combines art and science to help you create something beautiful.